Description

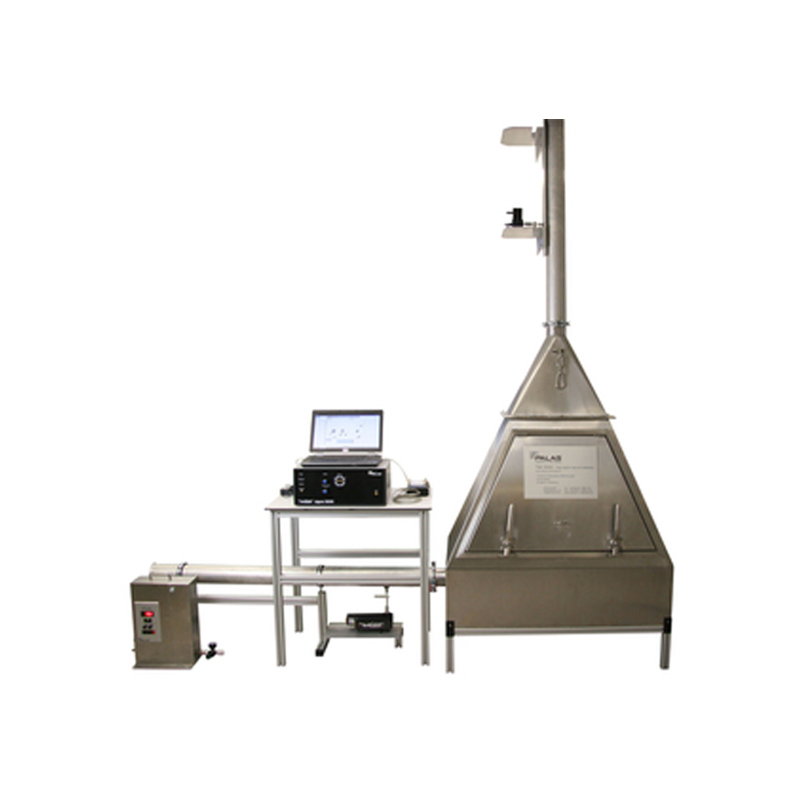

With the aid of the TVE 3000, vacuum cleaner tests can be carried out more cost-effectively than in accordance with the standard EN 60312. In addition, it is possible to distinguish the separation behavior of vacuum cleaners with bags and vacuum cleaners with bags and HEPA end filters reliably with with dust or as an option with salts – e.g. NaCl or KCl within the salt generator AGK 2000. The dust disperser RBG 1000 that is used operates much more uniformly than is required in the standard and therefore delivers an optimized dust application, which is a prerequisite for exact measurements of separation efficiency with a particle measurement device.

With the particle measurement system Promo® 2000 with the aid of the welas® 2300 aerosol sensor in the clean gas, the emissions of a vacuum cleaner can be measured in accordance with the standard. As a result, not only is it possible to accurately compare vacuum cleaners, but the individual filter stages can also be reliably assessed.

With the particle measurement system Promo® 3000, users have access to a high-resolution aerosol spectrometer for virtually simultaneous determination of the particle size distribution and the particle concentration in the raw gas and in the clean gas.

The welas® 2070 aerosol sensor accurately determines the measurement in the raw gas, while the welas® aerosol sensor 2300 performs the measurement in the clean gas, allowing the fraction separation efficiency of vacuum cleaner bags and HEPA end filters to be performed.

Function

Dust is introduced into the system using the dust disperser RBG 1000. The reproducibility of the dust concentration is < 10% in terms of quantity.

The welas® 2070 aerosol sensor measures the particle size distribution and the particle concentration in the raw gas (upstream of the vacuum cleaner). The dust is sucked in by the vacuum cleaner and separated out in the vacuum cleaner bag and in the HEPA end filter. The emissions from the vacuum cleaner are then measured with the welas® 2300 aerosol sensor on the clean gas side (downstream of the vacuum cleaner). From the measurements of the raw gas and clean gas, the fraction separation efficiency of the vacuum cleaner is determined.

The FTControl software allows many fraction separation efficiency measurements for different vacuum cleaners to be displayed at the same time on screen.

Both the dust disperser and the clean gas sensor can be positioned in different locations so that the influence of the flow channel on particle sedimentation can be investigated.

Position of the clean gas sensor: The aerosol sensor for the clean gas measurement can be positioned in two different locations.

Position 1 is the clean gas measurement point in accordance with the standard EN 60312.

The clean gas sensor can be operated either in position 1 or position 2, e.g. in order to investigate sedimentation and other transport losses in the suction channel. Position 1 complies with the standard.

Fig. 2: Clean gas sampling

Position of the dust disperser RBG 1000:

The RBG 1000 is attached as shown in Fig. 1 in accordance with standard EN 60312 or frontally positioned at the entrance of the flow channel, which ensures that no deposits can build up in the aerosol intake elbow.

Measurement of the fraction separation efficiency

From the measurements of the raw gas and clean gas, the fraction separation efficiency of the vacuum cleaner or the vacuum cleaner filter stages is determined.

Fig. 3: Measurement of the fraction separation efficiency of a complete vacuum cleaner including vacuum cleaner bag and HEPA end filter