Description

In order to reliably determine the quality and efficiency of filter elements, it is crucial to test energy consumption (pressure drop), loading and particle separation efficiency in addition to total penetration.

Accurate measurement requires adaptation of the test channel with regard to flow guidance and aerosol distribution to the size of the filter elements

Palas® has over 35 years of experience in the field of filter testing and continuously develops test rigs of the highest quality to meet a wide variety of requirements.

The FET 300 enables defined testing of filter elements up to 300 x 300 mm, such as ventilation filters, HEPA/ULPA filters, hoover end filters, car cabin filters.

Designed for optimum flow guidance, the channel can also be used for smaller filter elements by means of adapters.

Coarse filters up to ULPA filters are tested for separation via particle size as well as differential pressure. The FET 100 measures better than the standards require:

• ISO 24693-5 HEPA/ULPA filter elements

• ISO 16890 room air filters

• ISO 11155-1/3 Automotive cabin air filters

• DIN 71460 Automotive cabin air filters

Thanks to individual adapters and customer-specific adaptations in the air duct, the FET system can be used for a wide variety of filter elements.

Operating principle

A controlled fan sucks a defined test volume flow from the environment via a HEPA inlet filter through the test duct and a protective filter.

The aerosol and pressure are operated on the upstream side of the FET 300. In the vertically constructed test duct, the aerosol is then homogeneously mixed and directed onto the filter element.

The aerosol extraction for the particle measurement is representative on the raw and clean gas side, considering the isokinetic. Two measuring devices can be used simultaneously or only one measuring device with a measuring point switch.

The measuring instruments used are the Palas® U-SMPS or the aerosol spectrometers of the Promo ® system , which can cover a measuring range from 0.01 to 40 µm, depending on the selection.

Now the filter element is inserted into the test channel. The filter holder can be easily and quickly opened pneumatically for this purpose. Individual adapters can be made for different designs of filter elements.

Now the filter element is tested. The pressure drop and the clean gas concentration and size of the clean gas aerosol are determined and the fractional separation efficiency is calculated.

The system is easily controlled via the integrated FTControl test rig control system. Individual sequence programs ensure that the measurements are carried out safely.

A comprehensive analysis section allows simple and fast evaluation of the measurement results.

Extensions / Accessories

Aerosol generation

Due to the modular design, a wide variety of test aerosols can be generated depending on the aerosol generator used:

DEHS, oils, paraffin oil, NaCl or KCl, test dusts such as ISO A2 Fine.

Aerosol discharge

Depending on the application, the aerosol discharge is carried out via the electrical corona discharge CD 2000 or the X-ray source XRC 049 , which is not subject to approval.

Aerosol dilution

The dilution systems of the VKL series are to be used especially when measuring high HEPA filter qualities (filter efficiency >99.95%). When using dilution systems, a measuring point switch for the dilution factor (1,10,100,1000,10000) is used for easy filter testing.

Aerosol measurement

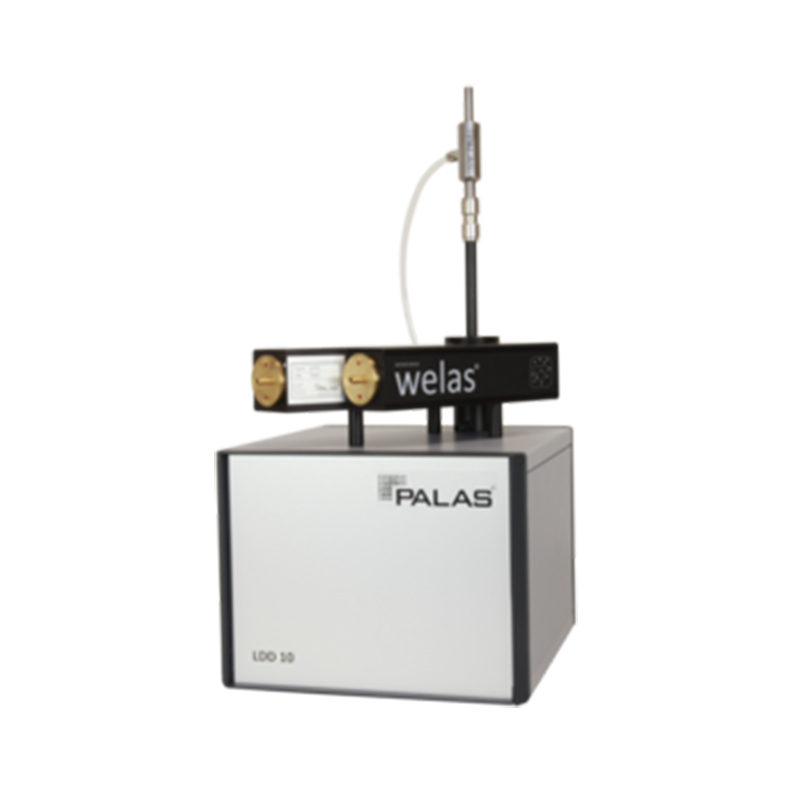

The aerosol measurement takes place

• in the range from 0.01 to max. 1.2 µm with the Palas® U-SMPS ,

• in the range from approx. 0.12 to 100 µm with the aerosol spectrometer of the Promo ® system .

The two measuring instruments can be combined and used simultaneously as an U-Range for the entire range.